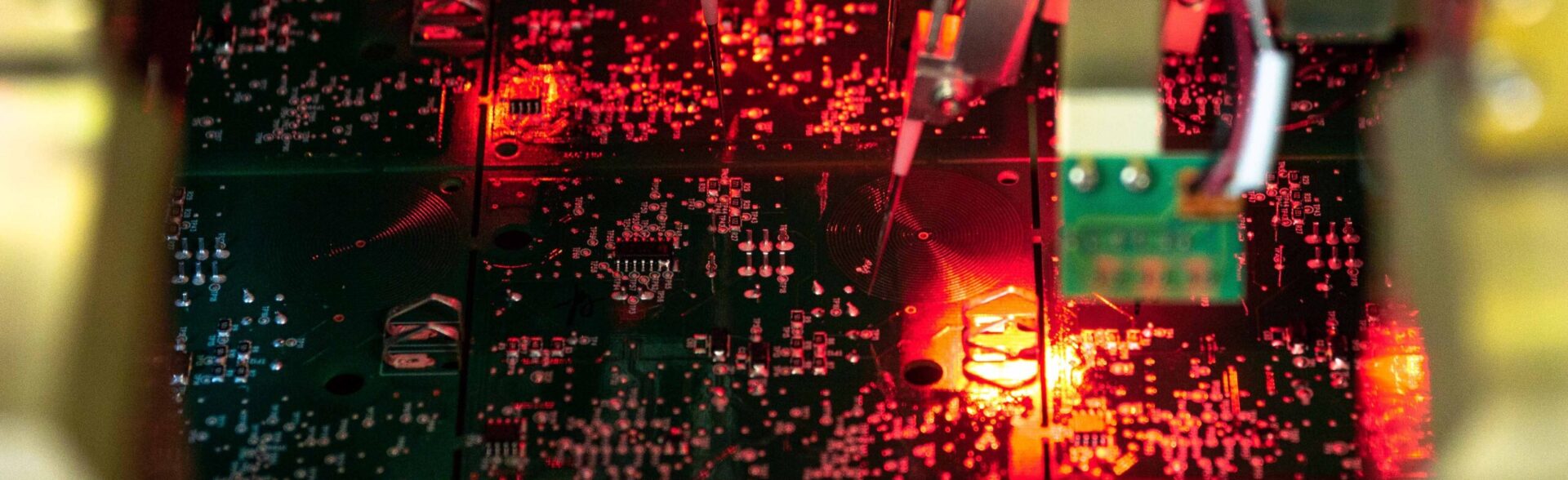

Our mission: to ensure successful market launch and sustainability of your electronic products through our innovative processes at all phases of your project.

Industrialisation Ensure a successful market launch for your electronic products

We can help you launch your electronic products at our production facilities based on specifications that you either design internally or in consultation with our engineering teams. The aim of this preliminary phase is to identify any issues and ensure that the design meets your requirements, thus optimising your costs, processes, and the associated supply chain.

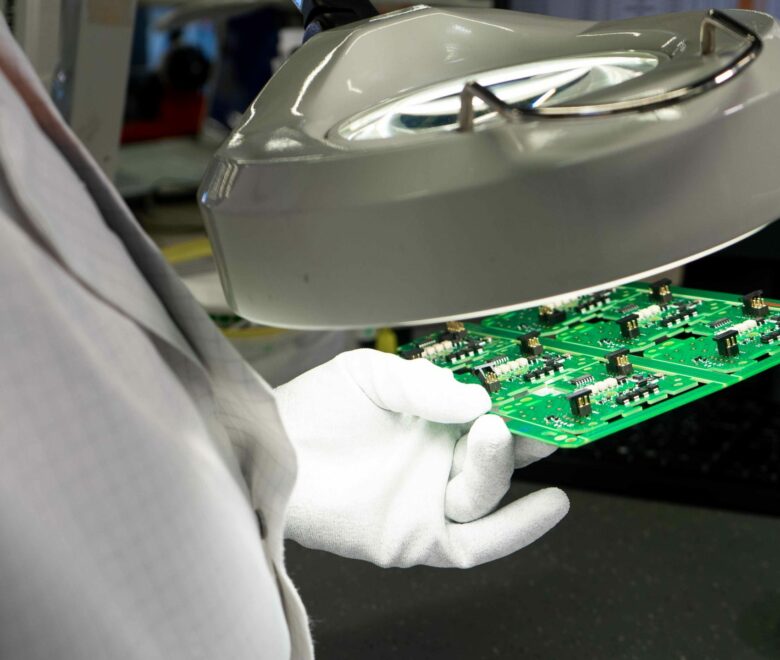

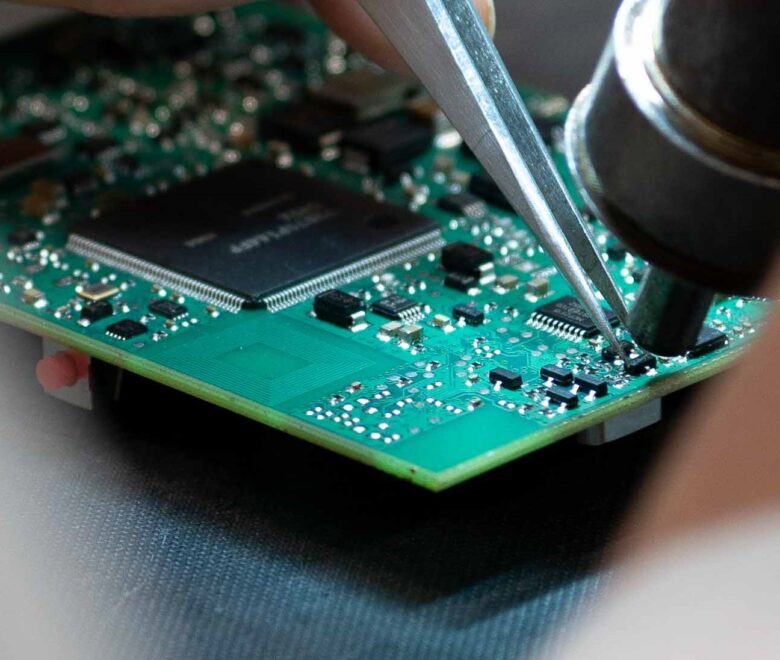

With expertise in developing functional, structural and regulatory test benches, our engineering teams are on hand to define the most appropriate testing strategy for your means and objectives. Our mission: to guarantee the quality of your products and circuit boards.

Pre-production Validate your products’ functions before they go into production

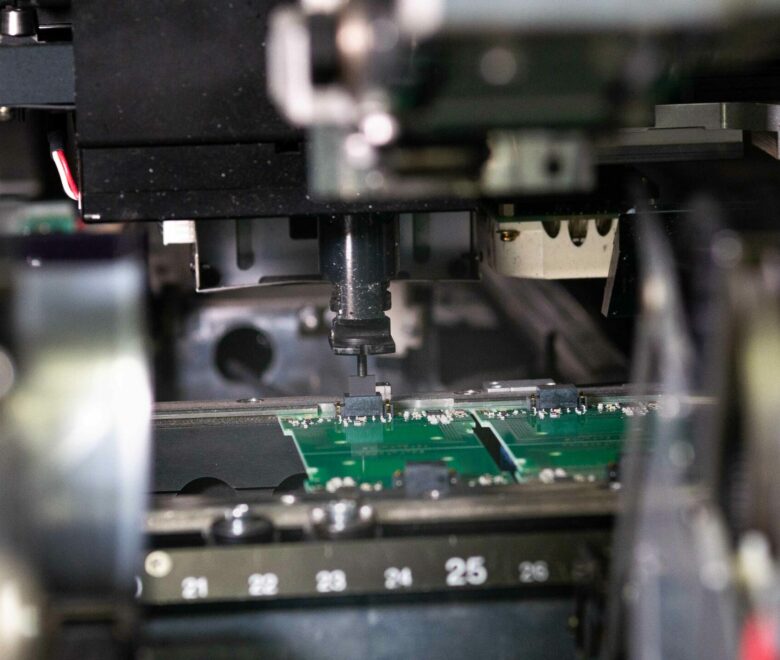

In this initial step towards a long-term partnership, we quickly deliver a pre-production run of your electronics boards and products. With our dedicated teams, flexible SMT lines and test/production equipment connected in real time, we can guarantee optimal responsiveness.

Our role is to validate your design and industrialisation to meet your requirements and improvement needs. We will analyse technological choices with you to determine key steps in the production process.

Manufacturing Manufacture at minimal cost in close proximity to your markets

We are a top European electronics player and experts in manufacturing processes. With capacity to assemble a wide range of products, we constantly seek to optimise production processes to meet your priorities in terms of quality, sustainability and competitiveness.

We offer a full and scalable package of solutions: assembly of rigid and flexible SMT boards, tropicalisation, in situ and functional testing, assembly of end products. Based on our significant automation capacities, we are able to minimise production costs and guarantee optimal quality. In line with our continuous improvement process, we draw on lean management techniques deployed at large-scale, an agile organisational structure, and responsive teams to optimally meet your requirements.

Kitting & shipping Optimise your inventory and streamline your shipments

In order to provide a global and bespoke service, our logistics centres are structured to meet both your regional and international requirements. We can manage your inventories of electronic products and accessories allocated for order picking at our sites (kitting process). We also ship by the batch or unit to your customers or installers. Our teams ensure full traceability of deliveries in real time by providing consolidated tracking information.

Our mission: to deliver on time and commit to continually improving service levels and reducing overheads and inventory costs.

Reverse supply chain and retrofitting Get the most out of your products

We can manage your electronic product returns flows and process goods to optimally extend their service life and optimise your costs. Our experts will perform detailed diagnostics and direct your electronic products to a processing cycle.

By applying repair and retrofitting processes, we can fully refurbish your products to minimise their environmental impact and meet your requirements (quality, cost, time).

From prototype to serial production for key industry players

We are recognised and chosen for our agile multi-product industrial expertise in areas including home automation, IoT, IT, security, medicine, broadband, SiP and test instruments. We will support you through a lasting and transparent relationship.